An in-depth look at SMART MANUFACTURING, The solution from AIS x OMRON transforming Thai factories to Industry 4.0

Industry is the major force behind the revitalization of the Thai economy. The COVID-19 pandemic brought national development to a halt because it caused a major slow down in every sector, including industry. In fact, we cannot let national development remain at a standstill, no matter how dire the situation.

That’s where digital technology comes in, to play a central role in the transformation of the Thai industrial sector. AIS Business 5G has found answers for the manufacturing sector and has formed an partnership with Omron Electronics Company Limited or OMRON, the leader in Smart Manufacturing and Autonomous Mobile Robots, to more fully utilize AIS’s 5G network and digital technology in helping upgrade manufacturing with Smart Manufacturing solutions that can perfectly meet the needs of factories in Thailand.

AIS x OMRON สู่ Industry 4.0

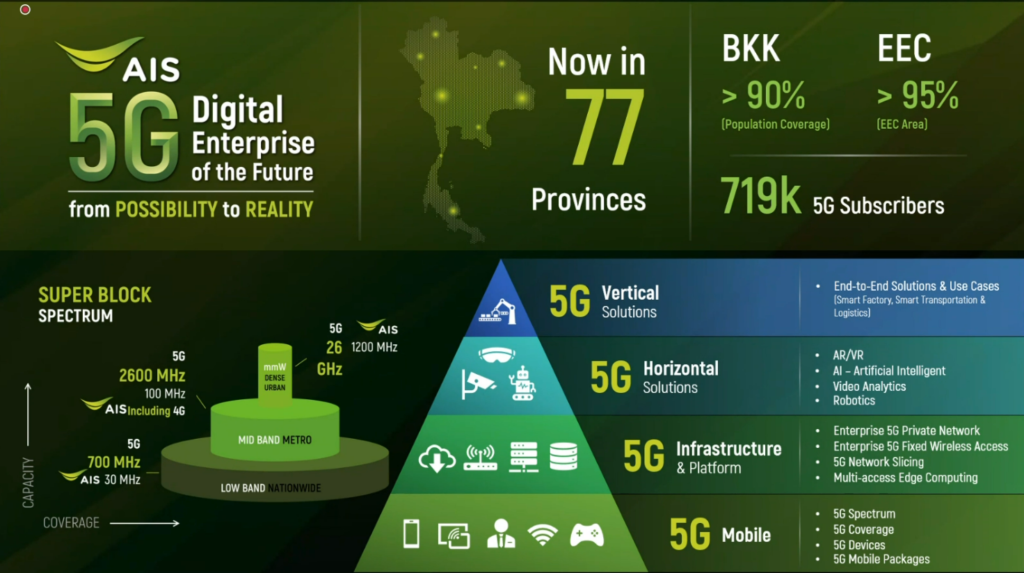

AIS is the 5G leader with signals reaching everywhere in the country and a variety of spectra for use at every level from 5G Mobile to 5G Infrastructure and Platform, 5G Horizontal Solutions and 5G Vertical Solutions. AIS is determined to create the greatest connectivity to meet the needs of people in Thailand and has introduced cutting-edge technology to provide powerful new solutions for many industrial sectors, including manufacturing. AIS is determined to help lead the Digital Transformation and make it a reality to promote growth of the digital economy. AIS has made agreements with several diverse partners and built up a strong team of skilled professionals to offer a range of digital technology solutions.

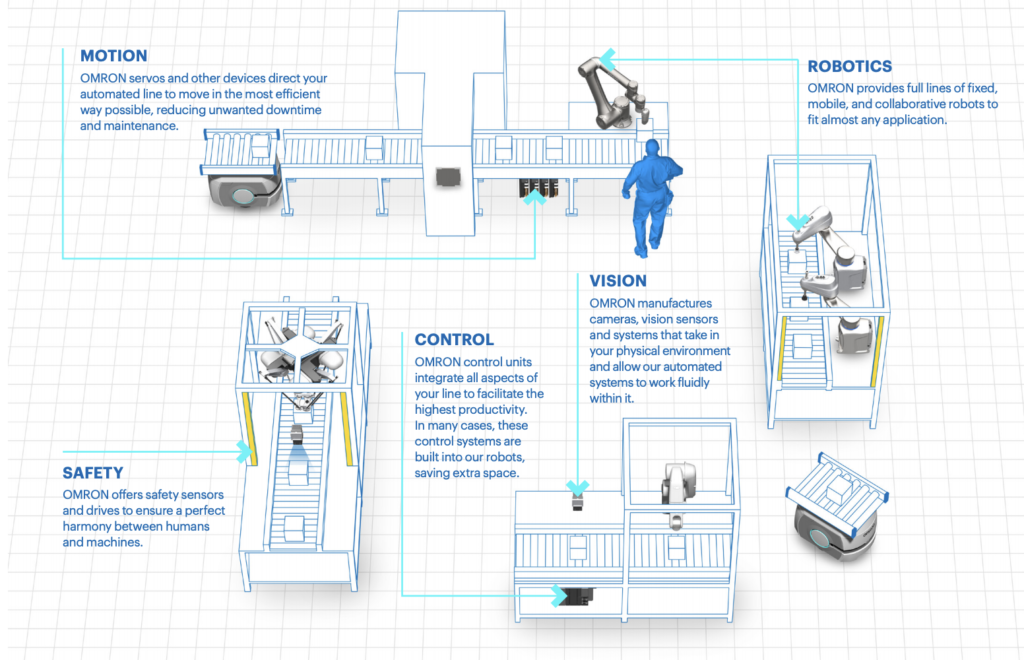

OMRON is a technology leader in manufacturing, services, automation systems and robotics. It has been working closely with all kinds of industries like the automotive industry, automotive parts makers, electronics, electric appliances, parts and semiconductors, food and beverage, consumer goods and pharmaceutical for over 88 years. OMRON provides both technology services and engineering services. It utilizes comprehensive technology to offer Smart Manufacturing solutions that encompass ways to connect manufacturing data networks with IoT systems, robot development and artificial intelligence (AI) applications in the production process, all of which are in the right stream to achieve Industry 4.0.

Due to the specialized expertise of both companies, AIS decided to sign a memorandum of understanding (MOU) with OMRON to present Smart Manufacturing solutions that combine communications technology with manufacturing technology. These solutions will connect Information Technology (IT) like Internet of Things (IoT), Network & Connectivity, Cloud and Cyber Security to work with Operation Technology (OT) used in industry like Real-time Monitoring, Machine Control, Automation, Robotics and Machine Vision. This is a sustainable path to Industry 4.0.

Smart Manufacturing สู่ Smart Factory

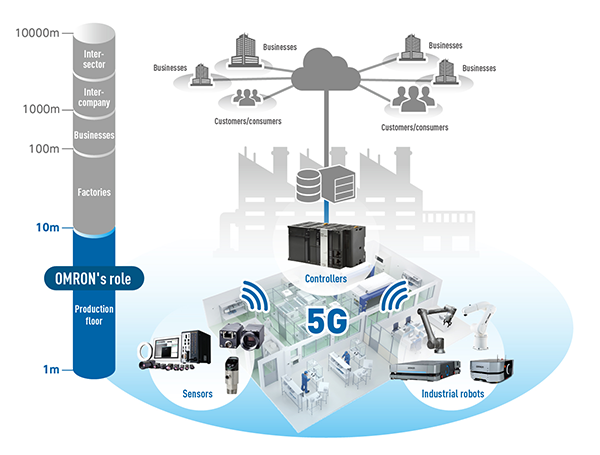

Industry 4.0 and Smart Manufacturing on the AIS 5G platform and digital platforms like Cloud, IoT or Cyber Security can be customized for use in specific factories, like a 5G Private Network that offers extra security and reliability. It can be tailored to the needs of factories that use precision manufacturing. It is essential infrastructure to develop industries in the digital era. Data from machines on the production line can be transferred via IoT technology to the administrative system to help in production planning and resource allocation. The Smart Factory system also comprises robotics and automation.

Some of the technologies used in Smart Manufacturing solutions include remote control technology and AI that can be combined with Machine Vision, IoT Smart Sensors, robotics and automation. These combined technologies can form systems that are models for intelligent manufacturing, like

- Autonomous Mobile Robot (AMR) can read a map to determine its path with no need for dedicated guide-lines. The map is built by sensors scanning the robot's surroundings, and results in the quick and easy movement of material, all supported by the 5G Private Network.

- Layout-free Production Line is a solution enabling a flexible production line which can be altered according to production needs and necessities of space, among other limitations. It supports management of a range of production lines, with the designs changed quickly according to the work. This leads to cost savings, greater flexibility and responsiveness and the ability to get goods to market very quickly.

- Sensors high-definition lenses and other equipment can capture data on every aspect of your production line and monitor how your machines are working. That data can then be processed by AI to predict any errors. With close monitoring you can usually detect and solve problems before they occur.

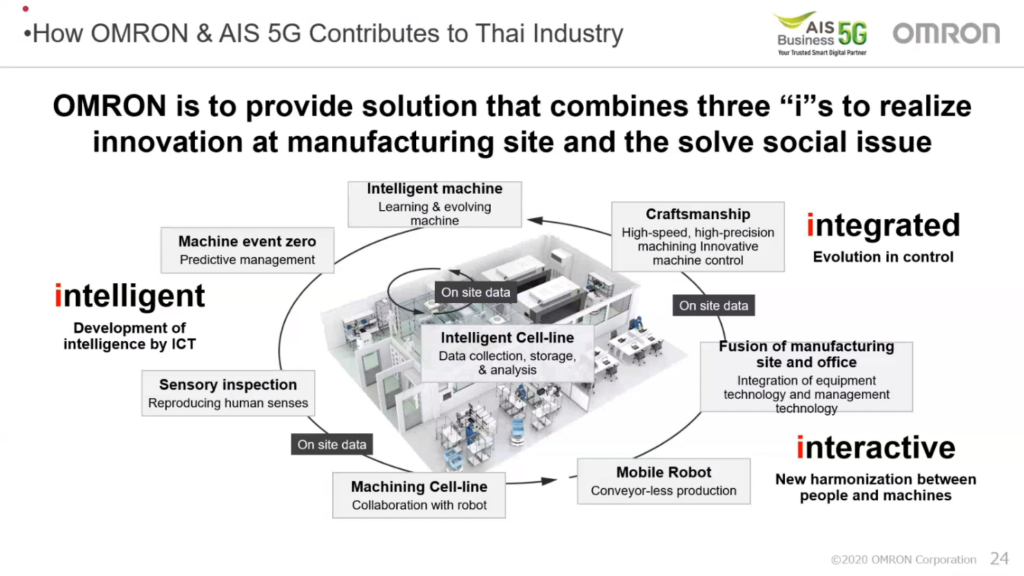

In addition, OMRON presents solutions based on the 3 “I”s of Smart Factory innovation:

- Integrated: incorporating advanced technology quickly and accurately

- Intelligent: using Big Data to let the production system learn and develop itself

- Interactive: humans and machines can work together smoothly with no difficulties

When you combine the 3 “I”s of Smart Factory management with AIS 5G, you can link the production process to the logistics system, and link central management to all the factory floors very efficiently.

Thanks to the speed and stability of the AIS 5G network, data can be distributed widely, both in terms of geographical area and signal penetration, and in terms of the diversity of devices that can be reached, including different kinds of sensors and robots. Every unit and component of the production system can be linked to the management system with complete security under the 5G Private Network infrastructure.

Development of a Smart Manufacturing system using 5G is the answer to many of the challenges faced by today’s enterprises, such as:

- Managing production and managing resources when you have a variety of products or several different production facilities

- Controlling costs by making use of real time data on expenses, waste, and production stoppage

- Implementing Overall Equipment Efficiency (OEE) by utilizing detailed real time data on raw materials management and production process management

- Saving labor costs by introducing some kinds of robots for functions such as assembly and inspection

- Maximizing worker safety and making sure people work together with machines smoothly

- Efficiently managing raw materials and inventory

- Conserving power and using energy more efficiently

- Preserving the natural environment and being sustainable for the good of the community and society

Also, converting your production to the Smart Factory concept will open up new capabilities for your business to become more adaptable by implementing Flexible Manufacturing, Small Lot Size Production, Traceability and Predictive Maintenance.

This collaboration between AIS and OMRON is a synergistic partnership. AIS is the leader in 5G networks in Thailand and OMRON is a leader in Smart Manufacturing and Autonomous Mobile Robots, so together we are fully prepared to offer Smart Manufacturing solutions for Thai industries.

You can learn more about AIS’s services for enterprises at https://business.ais.co.th/ or from your AIS business representative.

Published 20 August 2021

AIS Business พร้อมเป็นพันธมิตรดิจิทัล ที่มั่นใจได้ เพื่อพัฒนาธุรกิจและสังคมไทย

เติบโต อุ่นใจ ไปด้วยกัน

"Your Trusted Smart Digital Partner"

ปรึกษาและวางแผนพัฒนาเทคโนโลยี เพื่อรองรับการทำงานและต่อยอดธุรกิจได้ที่

Email : [email protected]

Website : https://www.ais.th/business

© 2024 Advanced Info Service PLC. All rights reserved.